Introduction

Nucleation of ultra-thin metals is a key issue that limits the application of transparent conductive metal electrodes in flexible displays. Generally, the deposition of inert ultrathin metals such as Au and Ag follows the island growth of the Walmer-Weber growth mode. Defects generated during the nucleation stage will significantly reduce the transmittance, electrical conductivity and mechanical life of the deposited film. Therefore, nucleation-inducing layers are often used to promote the ultra-thin metal layered growth. Active metal materials such as Cr, Ti, Ni, Ge, and Cu have strong adhesion to inert metals such as Ag and Au, which can inhibit the diffusion in the nucleation stage, so they are often used as nucleation-inducing layers. However, the addition of a metal-induced layer often results in a decrease in transmittance, and is therefore gradually replaced by highly transparent dielectric materials such as ZnS, MoO3, and WO3, which are common dielectric layer / metal / dielectric layer structures. Recently, with the increasing demand for the bending performance of devices, it is urgent to develop a highly flexible organic induction layer.

Achievements

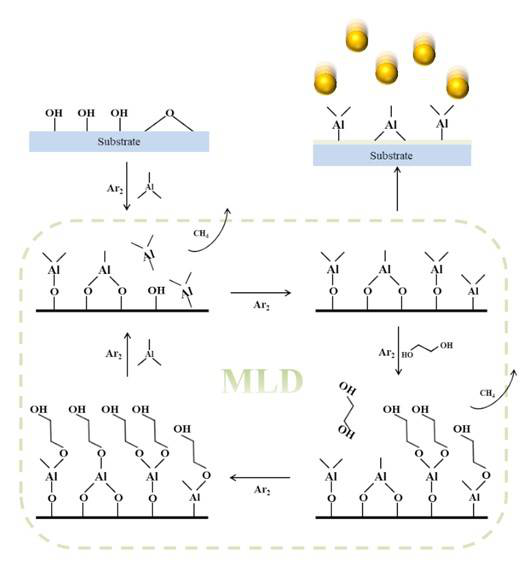

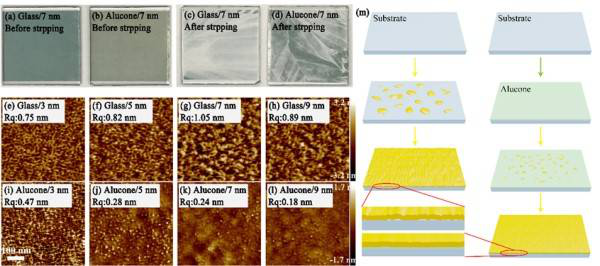

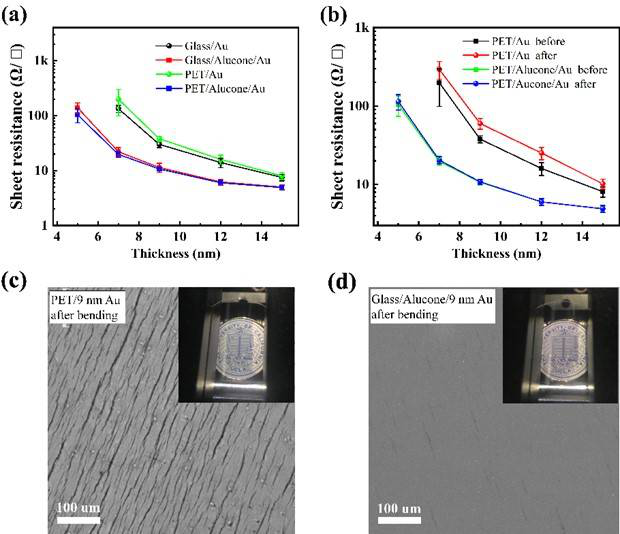

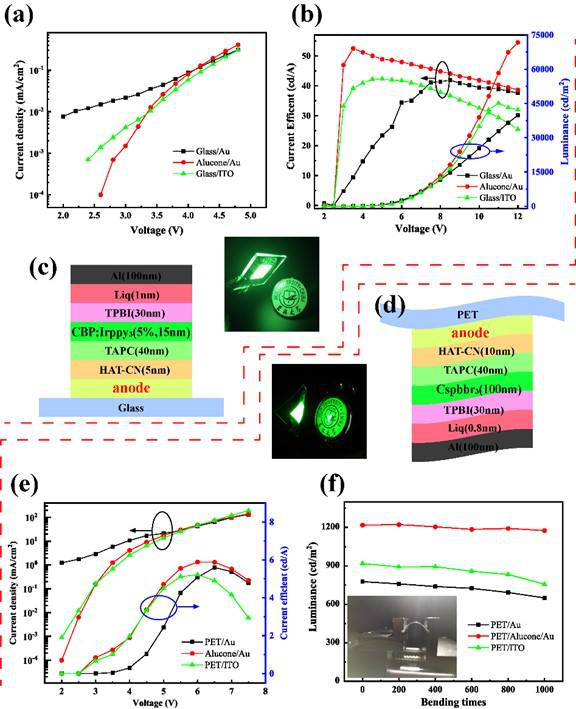

Recently, Prof. Duan Yu's team from Jilin University, Wang Haoran, and others prepared a methyl terminated organic-inorganic hybrid film as a nucleation-inducing layer of ultra-thin metal by molecular layer deposition. Molecular layer deposition is a chemical deposition method based on the reaction of surface groups, so the termination groups on the surface can be precisely controlled. Compared with traditional self-assembling functional group-terminated materials, the vacuum preparation environment of molecular layer deposition makes surface termination groups more active. The molecular layer deposited aluminoxane modified the hydroxyl and siloxy groups on the surface of the substrate to a highly active methyl group, thereby improving the nucleation of ultra-thin gold. The gold film deposited on the methyl-terminated aluminoxane thus avoids island growth and exhibits root mean square roughness below 0.3 nm. When this electrode is applied to a photovoltaic device, compared with an organic light emitting device using an ITO electrode, the current efficiency is improved by 24.4%. In addition, when the gold electrode grown by this method is applied to a flexible perovskite light-emitting device, it also exhibits an increase in current efficiency of 12.7% and remains stable after 1,000 bendings. These results demonstrate the application potential of the nucleation-inducing layer prepared by molecular layer deposition in organic optoelectronic devices and wearable devices. Related results were published in Advanced optical materials under the title "A Novel Nucleation Inducer for ultra-thin Au Anodes in High Efficiency and Flexible Organic Optoelectronic Devices".