Introduction

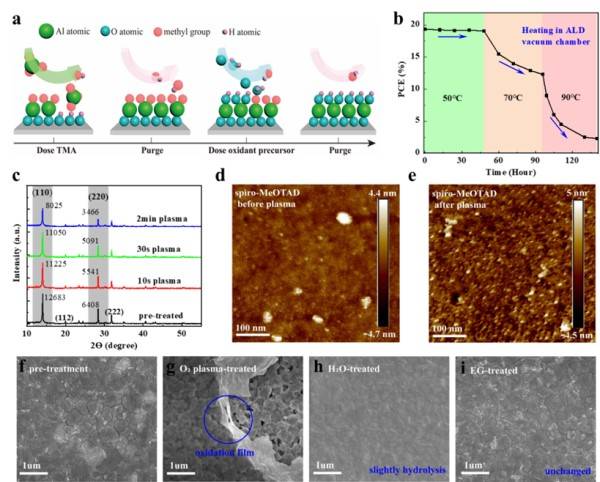

At present, the efficiency of perovskite-based solar cells is close to practical use, but external moisture will cause the perovskite layer, the hole transport layer, and the electrode / transport layer interface to degrade. Therefore, its stability in air is an obstacle. Bottlenecks that need to be practically addressed. Researchers have proposed many solutions: including passivation additives, water barrier transport layers, and water barrier interface modification layers. However, these methods of improving internal stability have not yet met the need for perovskite batteries to maintain stability in outdoor environments. In contrast, packaging methods performed outside the device, especially thin-film packaging, can choose water blocking materials in a wider range, the thickness of the active layer is not limited, and it is compatible with methods to improve internal stability, and finally realize the device Flexible and lightweight. However, compared to organic optoelectronic devices such as OLEDs, metal halide perovskite solar cells are more sensitive to temperature and active particles. Most of the existing packaging methods will cause damage to perovskite solar cells, so it is urgent to develop new high-efficiency non-damage Thin film encapsulation method.

Achievements

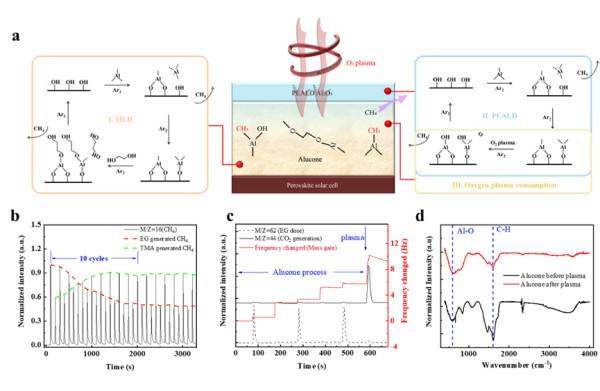

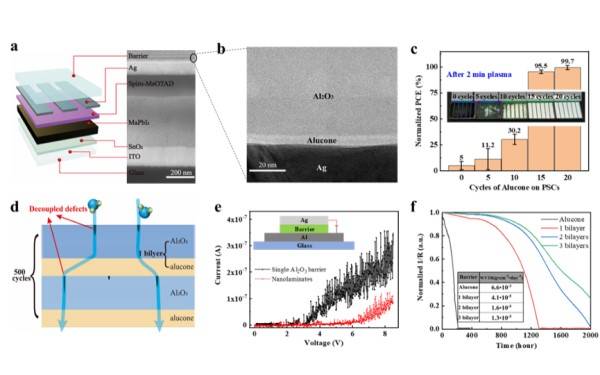

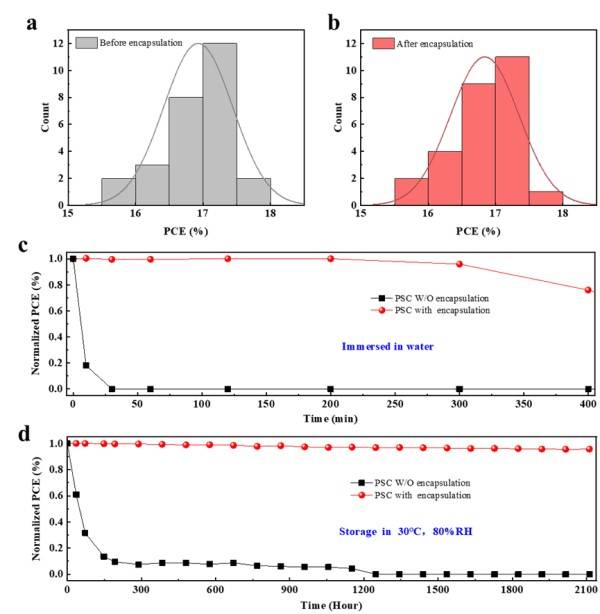

Recently, in the team of Professor Duan Yu of Jilin University and the team of Professor Yang Yang of UCLA, a methyl-rich organic-inorganic hybrid film was grown on the perovskite solar cell at low temperature as a protective layer for the packaging process For the first time, a remote plasma-enhanced atomic layer deposition technique was used to form a dense alumina film directly on the surface of a perovskite battery as a water vapor barrier. The methyl group inside the hybrid film consumes oxygen plasma that penetrates the film during the plasma-enhanced atomic layer deposition process, thereby protecting the perovskite solar cell from oxygen plasma damage. The entire packaging process is performed at 50 ° C, and the device efficiency after packaging is only 0.09% lost. The application of plasma enhanced atomic layer deposition makes the water vapor transmission rate of this composite packaging film reach 1.3 × 10-5 g · m-2 · day-1, which plays an important role in promoting the stability research and practical application of perovskite solar cells. effect. Related results were published in the journal Nano Energy under the title "Hermetic Seal for Perovskite Solar Cells: An Improved Plasma Enhanced Atomic Layer Deposition Encapsulation". This result laid the foundation for the application of thin film packaging in the field of photovoltaic devices, and opened a new path for the practical application of perovskite-based solar cells.